This is the third in a five-part series that looks at how some specific industries are tackling Digital Mastery. In this post, we explore the manufacturing industry.

The manufacturing industry, much like telecommunications and healthcare, is facing a digital crisis. Although some organizations have embraced digital as a way to redefine the customer experience or even the business model, few, if any, have carried out the same level of transformation with their business processes. The difference between this industry and others, though, is that failure may not necessarily be entirely their fault. Manufacturers are beholden to an ecosystem of software in their value chain that may or may not communicate with each other, a sentiment echoed in the McKinsey report, “Digitizing the Value Chain[1]:”

Across industries, executives at several manufacturers identified a need for dramatic improvements in certain software applications. Reporting dissatisfaction with some vendors’ products in areas such as computer-aided design (CAD), enterprise resource planning (ERP), and manufacturing execution systems (MES), these executives cited examples of applications they found too hard to learn, too slow to evolve and adapt, and sometimes too expensive for small businesses. Some systems are also closed—they don’t communicate with each other or allow others to build upon them.

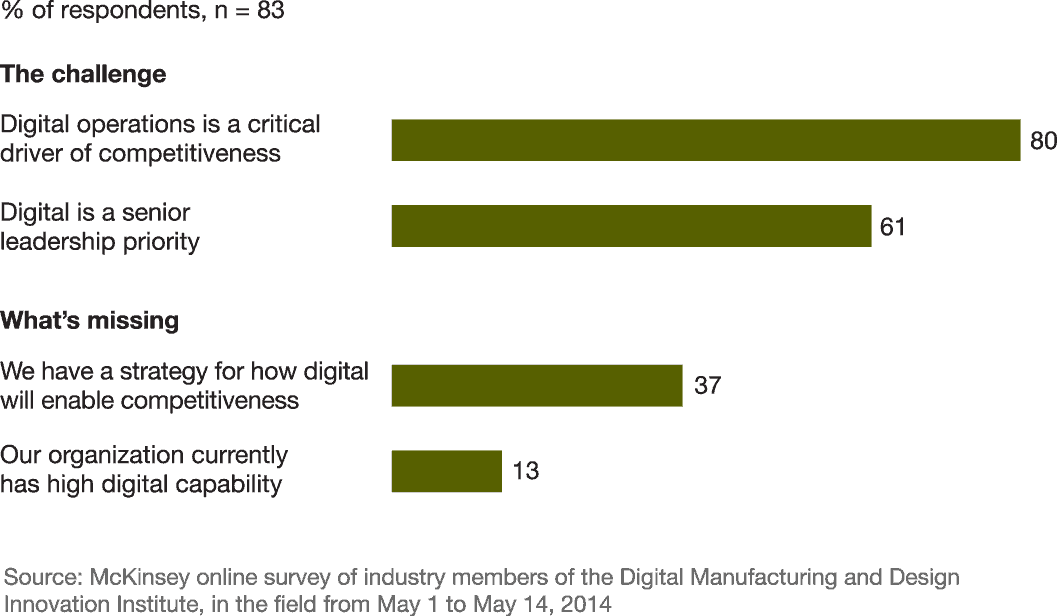

Yet, even if manufacturing companies feel the pinch of value-chain software not being open, flexible, or available in the cloud, they understand the value of digitizing their business operations as part of digital transformation:

For manufacturers, then, digital transformation isn’t an easy task. Just by the nature of employing so much third-party software, creating a truly digital value chain will require some heavy lifting. But there are definitely examples in the marketplace that any manufacturing organization can look to for guidance.

Leading the Charge—Nike

As we uncovered in the previous posts in this series, in his book Leading Digital, George Westerman defines “Digital Mastery” as those organizations that,

…excel in two dimensions. They use digital technology to fundamentally change their customer experiences, internal operations, or business models. More importantly, they have the leadership capabilities to drive transformation in the company. These companies are adept at using new technologies to overcome old barriers and create new opportunities.

When it comes to manufacturing, there might not be a better example of Digital Mastery than Nike, who has been busy revamping the entire way that it approaches its business:

Nike laid off much of the staff who worked on its FuelBand in April 2014, signaling its move away from hardware in the fitness tracking market. Instead, it’s using its NikeFuel technology and Fuel Lab to build an entire ecosystem around digital fitness tracking that includes outside developers and hardware makers as well as consumers.

Instead of becoming a hardware manufacturer, Nike recognized that it would be better served by focusing on the software—a digital thread that it could carry through all aspects of its business. As a result, Nike is utilizing digital technologies to revamp the way they do business, creating an entirely new business model while shaping the customer experience and internal processes. But it’s not only their Fuel Lab that’s seen the benefit of this kind of leadership. Over the past years, they have been carefully creating a digital value chain throughout their organization, enabling on-the-fly customization of their core product—shoes. Through their NikeID program, they have unlocked the holy grail of “manufacturing on demand” by transforming the core of their business through digital technologies that manifest in supply-chain management, procurement, and especially the end-consumer experience.

But perhaps that’s a result of something more fundamental. As the McKinsey study pointed out, most manufacturers rely on third-party software to drive their manufacturing operations. What if Nike did something differently? What if Nike built some of their own software to meet their specific business requirements?

What’s Needed to Digitize the Value Chain?

Perhaps part of the problem with manufacturers digitizing the entire value chain lies in the reliance on technology that was not developed specifically for their needs. As McKinsey points out,

Successful implementation of digital-manufacturing solutions entails fluid digital communication across the value chain—this continuous flow of data is the digital thread. In response, a number of legacy software vendors, to their credit, are striving to capture a share of this new market. But it’s an open question whether they can move fast enough. The evolution of the consumer Internet does offer some insight for its more nascent industrial counterpart. Today’s consumer-based apps and cloud-based software, for example, are updatable, affordable for the masses, and intuitive to use. Manufacturing leaders yearn for design and manufacturing software solutions and for an app-store ecosystem that can reach the same bar.

With the building blocks of consumer-based technology readily available—cloud resources, web-based languages, and powerful, highly-scalable databases—it may make more sense for manufacturers to build what they need themselves using a platform like Mendix. This kind of approach, when coupled with those legacy vendors slowly opening their software (as they try to capture part of the “digitization” market that manufacturers are dipping into), could provide the level of innovation needed to truly digitize the entire value chain and is probably reflective of what a company like Nike has done behind the scenes.

What Consumers Want…They Can Make!

What does a future of manufacturing with a truly digital value chain look like? Thankfully, we don’t need to look very far as companies like Nike are exemplifying the characteristics of Westerman’s Digital Masters. Through its NikeID program, Nike has truly enabled “manufacturing on demand,” (which unlocks an entirely new revenue opportunity) and, in the process, re-imagined the customer experience, their own internal business operations, and the very nature of their business model (making shoes on demand).

But Nike is only showing us the tip of the iceberg when it comes to digital transformation. The advent and commercialization of 3D printing is bound to radically alter the way manufacturing companies create their products…and enable consumers to create them as well. Imagine a manufacturing company that is entirely digital—every element of their value chain is exposed through web services, managed by cloud-based applications, and encapsulated in a customer experience that enables complete manufacturing on demand. Now that’s digital transformation.

Being Nimble Isn’t “One Size Fits All”

Nike recognized that digitizing their business wasn’t the result of just applying a few systems but of changing the underlying fabric of what they do—new ways to operate the business (i.e., NikeID, Fuel Labs) required software that changed the supply chain which necessitated new customer experiences (i.e., to interact with that software and the data from it) both of which needed to be driven by committed leadership. And if our assumptions are right, the transformative process required Nike to develop some of its own technology—software to power the value chain from e-commerce store to product design.

However Nike accomplished it, the company truly epitomizes a Digital Master and reflects the kind of transformation that is going to drive manufacturing in the decades to come.

[1] https://www.mckinsey.com/business-functions/operations/our-insights/digitizing-the-value-chain