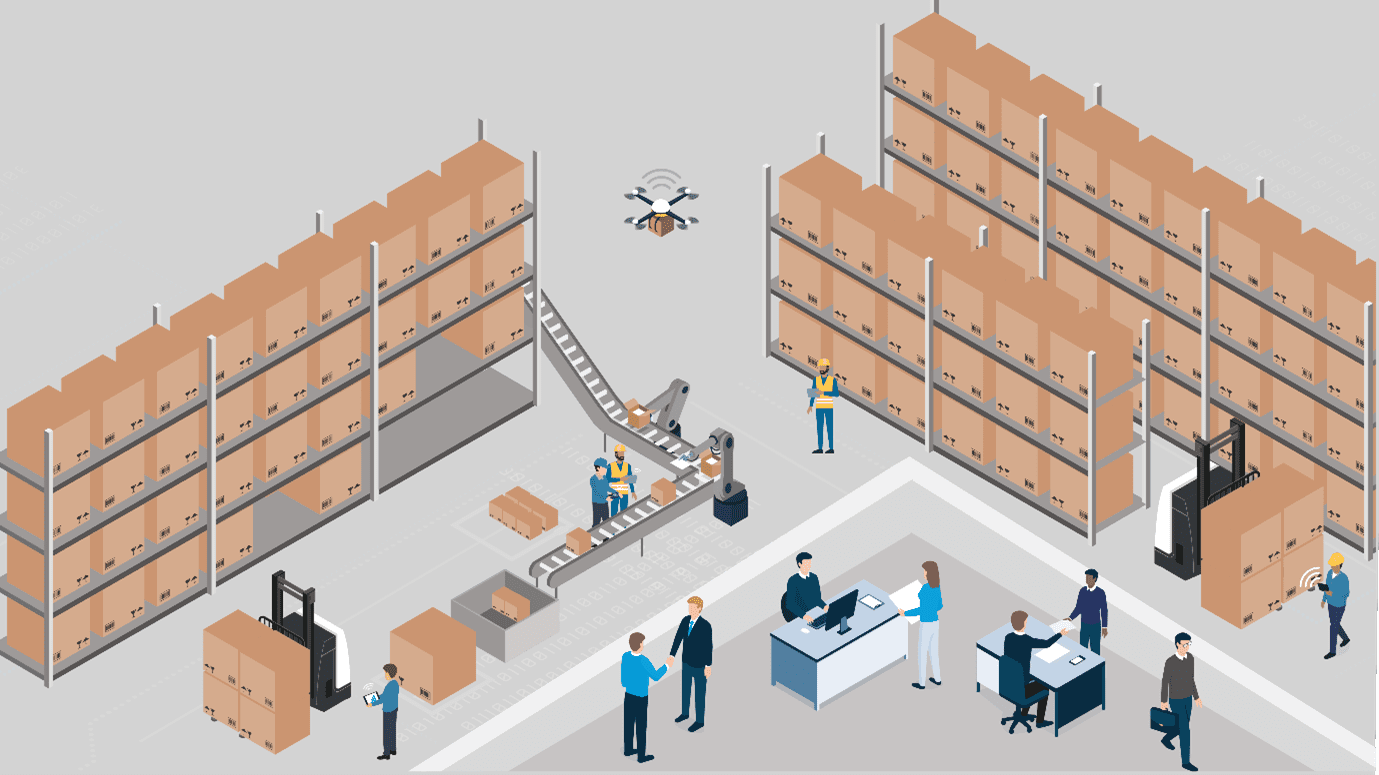

The Role of Mobility in Managing Warehouse Operations

Warehouse Management Systems (WMS) are becoming increasingly common in an effort to improve supply chain operations. However, to fully realize the benefits of a WMS, a mobility solution that digitizes key supply chain activities and eliminates manual processes is often needed.

It is widely acknowledged that the size of the market for WMS will increase, with a 2021 market analysis from Grand View Research predicting an annual growth rate of 15.3% from 2021 to 2028. This is expected to be driven by companies in the healthcare, manufacturing, and retail industries as they strive to streamline their operations to increase output and meet rising consumer demands. The set up of new warehouses to cater to increased customer demand, a change in supply chain models, the capability to ship products faster, and an ability to automate processes can all be attributed to the expected growth.

Real-time visibility

It is crucial that companies ensure they are getting the most out of a new WMS system. While the introduction of a WMS may improve the visibility of stock, orders, and movements throughout the supply chain, if data is inputted into the WMS manually, the potential efficiency and productivity gains will not be realized. It is also important to note that existing WMS solutions can also be enhanced with the integration of new technology to deliver improved efficiencies.

The key to processing and delivering orders on time, every time, is end-to-end, real-time visibility of data across the supply chain. It is crucial that every stock item stored, order received, and shipped delivery is accounted for and tracked through the warehouse process.

Completing warehouse tasks using manual processes or limited technology can cause stock discrepancies, order errors, delivery delays, and slow down operational performance. Implementing an effective mobile solution can transform supply chains, with the immediate benefits of improved stock accuracy, reduced processing times, and increased productivity being realized.

In addition to the clear stock traceability benefits, the transition from fixed desktop workstations to utilizing applications on mobile devices also significantly reduces walking time by eliminating the need to continually return to a desktop to input information. Automatically retrieving tasks on the go further adds to the boost in productivity.

Mobilizing the warehouse

While the 2021 MHI Annual Industry Report details 26% of companies using some form of mobile technology in the supply chain today, it is clear to see why it is predicted that 67% will adopt mobility solutions within five years.

- Real-Time Insights: Barcode and labeling innovations allow physical product information to be quickly and easily scanned by a mobile device, whether a tablet, ruggedized handheld, truck-mounted device, or wearable headset. The specific process undertaken by the operator can be recorded on the mobile device, which is updated directly to the ERP system in real time, allowing accurate and efficient tracking and processing of items through the warehouse.

It is not just about mobilizing individual processes, an intelligent mobile solution can connect all supply chain processes to ensure complete visibility of the end-to-end supply chain anytime, anywhere. This real-time insight is becoming a prerequisite within supply chain operations to meet demand and deliver a seamless customer experience.

- User Engagement: The use of mobile devices is part of everyday life, with warehouse operators already familiar with using mobile apps away from a work environment, making the transition to mobile technology an uncomplicated one from an end user perspective. Many end users embrace the introduction of intelligent mobility solutions as they make tasks quicker and easier to complete.

The intuitive user interface of many mobile solutions also significantly reduces employee onboarding and training times and makes the process of hiring temporary and seasonal staff to cope with peaks in demand much simpler.

- Analytics on Demand: The role of analytics within warehouse operations is changing, with a shift from analyzing data on a daily or weekly basis, to transitioning to real-time analytics that can inform accurate decision making to enhance current operations.

Access to real-time metrics anywhere, anytime, allows supply chain managers to interpret data on the move to influence stock movements, re-deploy resources and maximize asset utilization to ensure customer deliveries are always fulfilled on time and in full.

- Rapid Deployment: While the benefits are clear to see, the perception of large-scale business changes, operational disruption, and complex process migrations, alongside user hesitance, can often be a barrier to the implementation of mobility solutions.

There are several options you need to consider which can affect the deployment time. Will you be using your internal resource? Will you be working with a mobility specialist? Will you be developing a solution from scratch? Will you be using a low-code platform? Will you use an out-of-the-box solution? Sometimes the best way forward is a combination of these options.

Mike Kay is a partner account manager for The Config Team, a Mendix ISV Partner in the Mendix Solution Vendor Program.

Established in 1994, The Config Team has been solving SAP supply chain challenges for some of the world’s biggest brands for over 27 years. We design and implement intelligent SAP supply chain solutions that drive process excellence across the end-to-end supply chain, including PreBilt™ powered by Mendix, our user-friendly mobile solution that digitises any transaction within warehousing, manufacturing, and distribution centres.