Centralize Manufacturing Systems Across the Product Lifecycle

Manufacturers produce and process mountains of data each day. However, few have been able to harness that data and surface it in a way that is useful for their employees to improve business outcomes.

With 2,300 global employees, Mercury Systems is responsible for delivering an array of mission-critical technologies, ranging from microelectronics to encrypted storage devices, to the aerospace and defense industry. “We sit in the intersection of high-tech and defense,” said VP of Application Engineering, Anu Mishra.

In 2020, Mercury adopted the Mendix low-code platform to deliver the same cutting-edge digital solutions for their employees as they do for their customers.

Delivering a singular interface to connect and present data between business and engineering systems of record is an ideal future state for most manufacturers, and for Mercury Systems this is becoming a reality as they align a business-driven vision with leading platform technologies.

At the Mendix Manufacturing Forum in December 2022, Mishra detailed how Mercury made the leap from getting started in 2020 to a portfolio of 20+ low-code applications delivering on digitization.

Big-Picture Thinking

A defining characteristic of Mercury Systems’ success is that Mishra and his executive team do not approach digital transformation solely as a technology initiative – but rather as a business vision that should be supported with technology.

“We have visionaries, like our CEO Mark Aslett, who took a top-down approach,” recounted Mishra, “We were tasked with coming up with a set of programs to start with and lay out our digital thread journey.”

“The term digital thread was used in the Global Horizons 2013 Report by a global science and technology vision task force,” he continued. “Even in that report, it’s mentioned that it can mean different things to you. For us, we focused on our entire product cycle.”

Mishra and the team conducted an evaluation of platforms which could support the ‘digital thread’ vision while meeting Mercury’s requirements to be highly secure, compatible with systems of record, and cloud-native.

Upon determining that Mendix was the right path forward, Mishra and his team took a measured approach to set themselves up for long-term success and avoided biting off more than they could chew (a common mistake in the early stages of transformation).

A Phased Approach, From Start to Scale

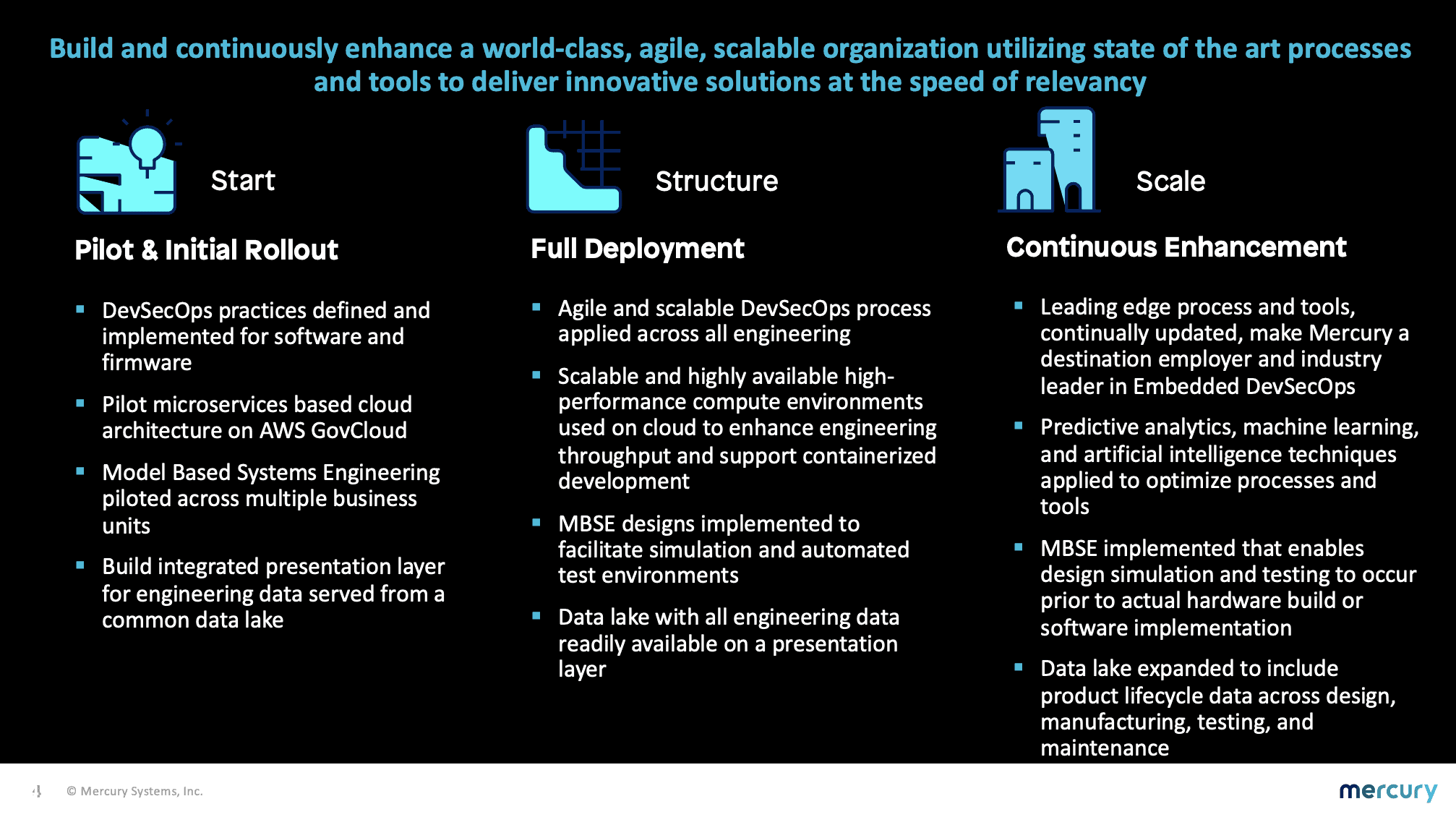

With their transformation platform in place, Mercury Systems adhered to the Mendix digital execution framework for low-code development.

“Mendix has a start, structure, scale way of implementing low-code,” said Mishra. “We started looking at the business goals and wanted to first deliver on cloud transformation and cloud strategy – so how do we get that groundwork defined?”

Getting Started: A Foundation for Multi-Platform Success

For Mercury, the start phase was focused on the architectural foundation and principles which would set the team up for long-term success. Like many organizations in highly regulated industries, Mercury Systems wanted to reap the benefits of new technologies and cloud transformation, but had to do so in the confines of an on-premise environment.

“We conducted a thorough study of how to go live with this, and it could not have been with a traditional approach because speed was of prime importance… And just because we were not directly on the public cloud does not mean you can’t be on cloud,” said Mishra.

“And we still kept it within our network. We have access to all the technologies, but it’s still secured within our firewalls.”

Due to the cloud-native nature of Mendix, working and deploying seamlessly to AWS GovCloud would allow Mercury to keep up technologically with their new development processes, such as working agile, establishing a DevSecOps capability, and a CI/CD pipeline.

“In phase one we defined DevSecOps practices, including an agile development approach… I didn’t want to wait to deliver in a traditional approach, because if you have to wait five or six months for one integration to happen and then go live with a broad, monolithic approach, by then you’ll have other problems to deal with and the solution could be stale,” said Mishra.

Structured Success: Bringing Disparate Data Together

Mercury Systems proceeded to the structure phase of development in December 2021, and today has 20 live applications which are deployed within a containerized, microservices-based architecture.

“At this phase, we are moving from a product-based to a program-based delivery model, which requires us to define a standard way of managing the programs.”

Standardization in the structure phase was critical given the complexity of Mercury’s platform landscape, which includes tools such as Jama, Salesforce, Cadence, and Cameo, all of which hold critical customer and engineering information.

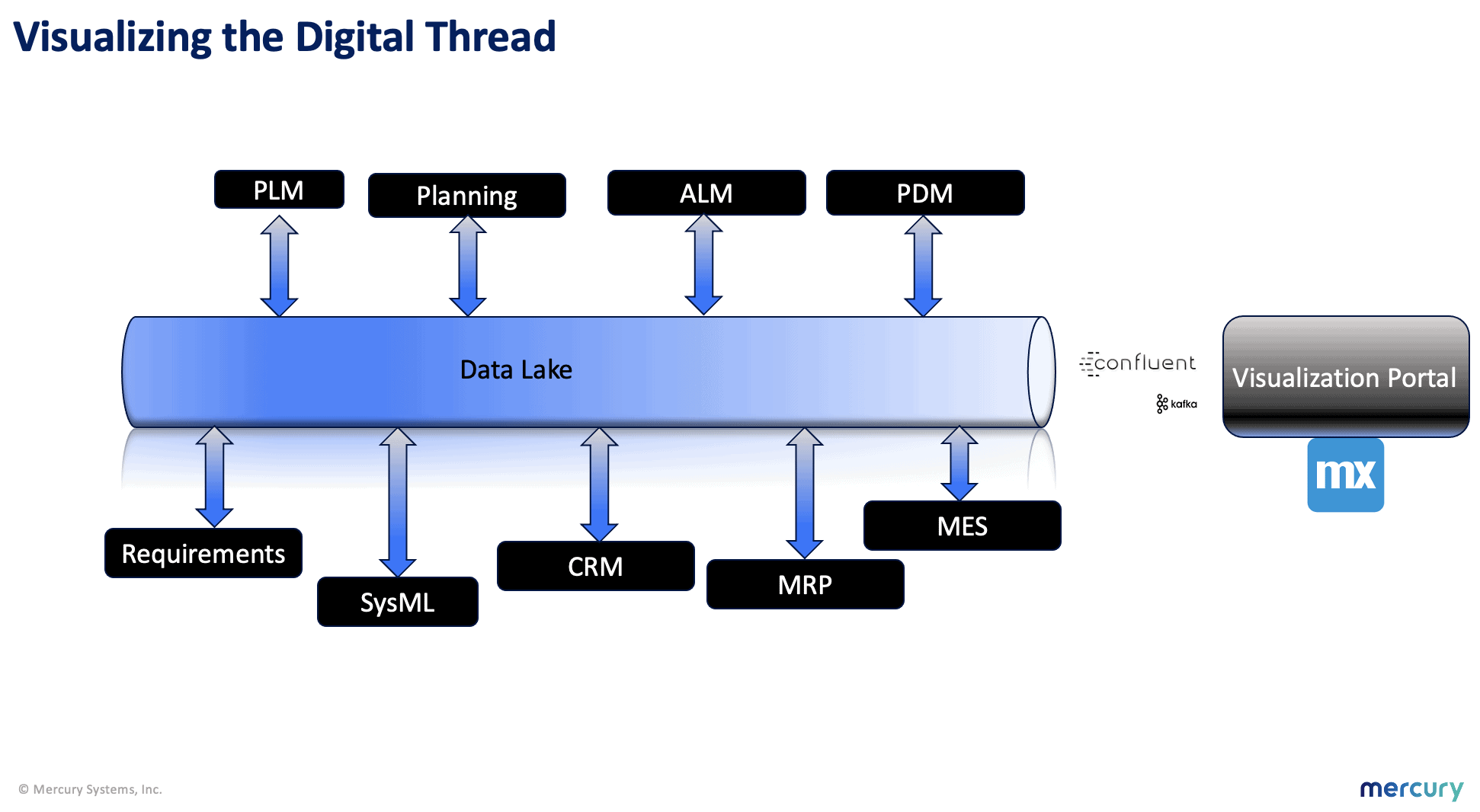

“To meet these high levels of complexity we needed high-performance computing environments… And the data lake formed a major part of this platform,” said Mishra. “Having so many different integrations and stages of the product lifecycle, if you start out in Cameo, how does that then interact with the rest of the ecosystem? Where does PLM come into the picture? Where do interactions with the CRM occur? And we are talking about a gamut of different applications there. This is where we made data lake a very central part of this platform.”

Developing to Scale: Extracting Actionable Insights

Mercury Systems is well on their way to development at scale, where Mishra has set priorities around even higher levels of interconnectivity and moving past simply connecting data – but using it to make proactive business decisions.

A Centralized View Across the Product Lifecycle

The emphasis on a sound architecture has made it possible for Mercury to successfully deliver the visualization layer of their engineering systems with Mendix.

“If I am a mechanical engineer and my daily work is in SolidWorks, I’m going to keep going there every day. I shouldn’t have to go search for the latest and greatest in some system, plug into another system, maybe find that I have a question, and then need to look to a colleague outside those systems,” Mishra summarized.

“That connection had to be made. A good example is Google – do they really store everything that you see in the search results? No, but it’s a quick way to find that information which is stored elsewhere. That was our idea for this visualization portal.”

Today, Mercury’s engineers can go to the Visualization Portal for a holistic product view. If they need to open up a schematic and access its many variants, the portal will pull in the appropriate data from Cadence or PLM systems, and they can see this information side by side.

“It’s just a page that they see, and it looks very much like Cadence, but it gives them a BOM comparison. They can rely on that data because it’s the latest and greatest, being fed into this layer from the data lake. They’re visualizing it in a Mendix interface, and it’s surfacing things from their application of choice,” said Mishra.

Transparency and Innovation in Manufacturing

Mercury has set a strong foundation as they scale up their visualization layer offering, as well as other applications across the organization. Having a common platform which can centralize historically disparate tooling is offering greater transparency throughout the product lifecycle – and introducing new areas for innovation.

The Mendix visualization layer makes it easier for Mercury’s employees to:

- Follow contract chains

- Track reviews and approvals

- Tie that to what is reflected in their ERP

- Keep product delivery on track.

Having a common visual layer which is highly compatible with PLM systems has also enabled Mercury Systems to bring cutting-edge manufacturing functionality into their applications.

“We were looking at different visualization formats, and it’s very neat to look at. The visualization files look cool, but you can also do markups on them. You can rotate the model staying at the shop floor, and people are now adding augmented reality into the mix. We wanted to take advantage of that, so we used the Mendix 3D Viewer, which was just released at the time.

“As part of this whole visualization concept, you can actually rotate your drawing or your final assembly from SolidWorks, without ever having to go into SolidWorks. We are extending that to the markup process and ECO which is coming soon,” Mishra shared.

In the future, the digital thread will ideally extend beyond Mercury Systems’ internal users, and customers and suppliers would have a portal view to look at models, add comments, and see their input directly reflected in the system’s engineering.

For Mishra, the combination of agile work, a cloud and microservices-based architecture, and low-code development is empowering his team to deliver solutions at a pace that not only meets, but exceeds, the business demand, solving a decades-long challenge faced by many IT teams.