Legacy Lag Costs You Big

It's Broken and You Need to Fix It

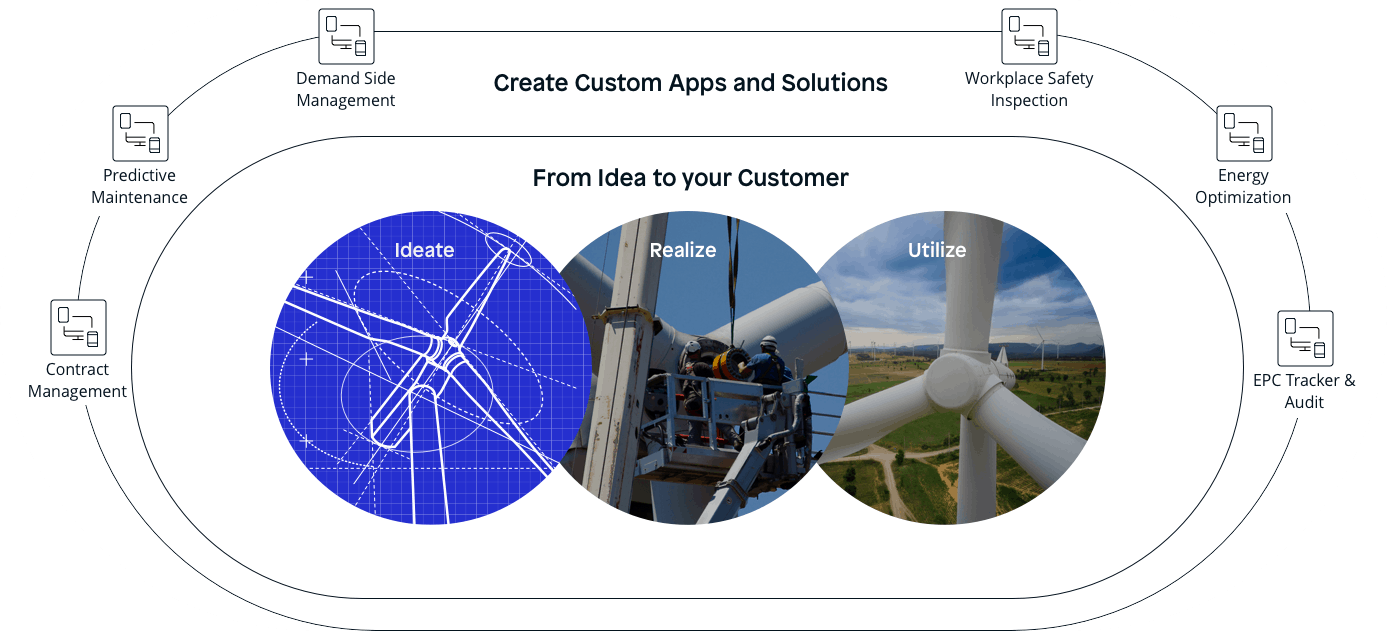

Evolve with Mendix

Energy and utility companies are using Mendix to keep pace in a rapidly evolving digital landscape.

The digital twin is a precise virtual model of a product or a production plant. It displays development throughout the entire lifecycle and allows operators to predict behavior, optimize performance, and implement insights from previous design and production experiences.

You can gain tremendous value from exploring “What if?” scenarios and predicting future performance with the digital twin. The ultimate goal of the digital twin is in the closed-loop connection between the virtual world of product development and production planning with the physical world of production system and product performance.

Through this connection you can gain actionable insight from the physical world that wilt fuel informed decisions throughout the lifecycle of products and production operations.