Mitsubishi Elevator Creates an IoT-Enabled Remote Monitoring System

Mitsubishi Elevator focuses on the continuous improvement of technologies, services, and business processes so that they can provide the best possible product and experience to their customers. Supplying elevators to 92 countries, they have been recognized as a high-quality supplier since they started in Veenendall, The Netherlands in 1951.

With an increasing focus on automation, utilization, data gathering, and IT processes, Mitsubishi has been continually exploring solutions to help improve customer experience and create operational efficiencies.

Evert Visser, Managing Director of Mitsubishi Elevator Europe, joined Mendix World 2021 to demonstrate how Mendix, along with TimeSeries, helped facilitate new maintenance applications that integrate product data and lifecycle into a single solution.

Differentiating through Service and Technology

The mission of Mitsubishi Elevator, according to Visser, is to use “state of the art technology, equipment, and principles to keep our customers happy and challenge ourselves every day to do it better tomorrow.”

Mitsubishi has demonstrated their mission through a phenomenal product and embrace of new technologies. They’ve adopted lean philosophy, smart industry, and smart factory principles over the past several years. All Mitsubishi elevators have remote monitoring as a standard feature. Further, their proprietary Move system allows sales managers to build out auto-generated quotes and mockup drawings for their customers by answering just a few questions.

Increasingly, though, the “elevator becomes a commodity more and more like your washing machine in your house,” said Visser. “You don’t know the brand.” So, Mitsubishi realized that the differentiator was less in the elevator itself, and more in the technology, guaranteed uptime, and value provided around an elevator.

The robustness and flexibility of low-code provided an avenue to meet all those needs head-on. To realize their big ambitions rapidly, Mitsubishi adopted the Mendix development platform and enlisted TimeSeries to support their implementation.

A Quick Response with Low-code

The COVID-19 pandemic presented an immediate issue that proved to be a strong proof point for Mitsubishi and low-code.

With fears over contact in public spaces, Mitsubishi partnered with TimeSeries to develop a consumer-facing app. This app allows anyone to scan a QR code from either outside or inside an elevator and select a floor, rather than having to push a button. This app was developed in only 2 weeks and demonstrated Mitsubishi’s commitment to quickly respond to consumer needs.

Creating the Building Blocks for Integration

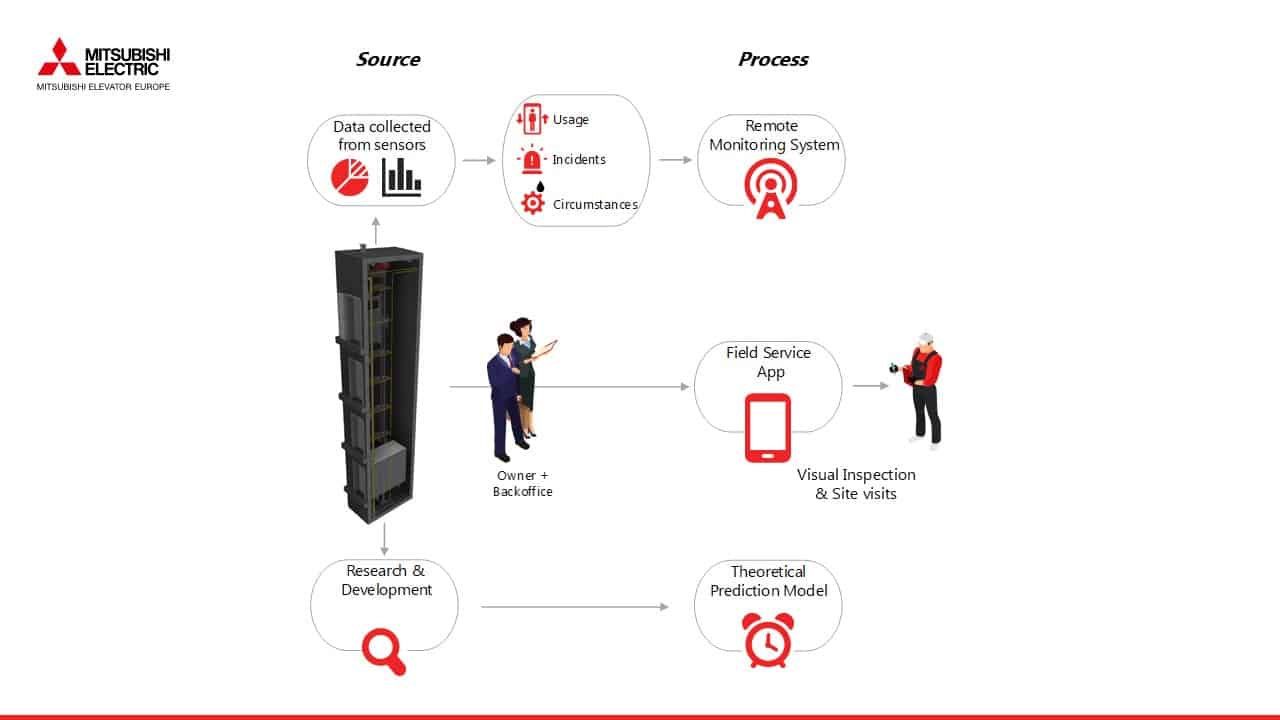

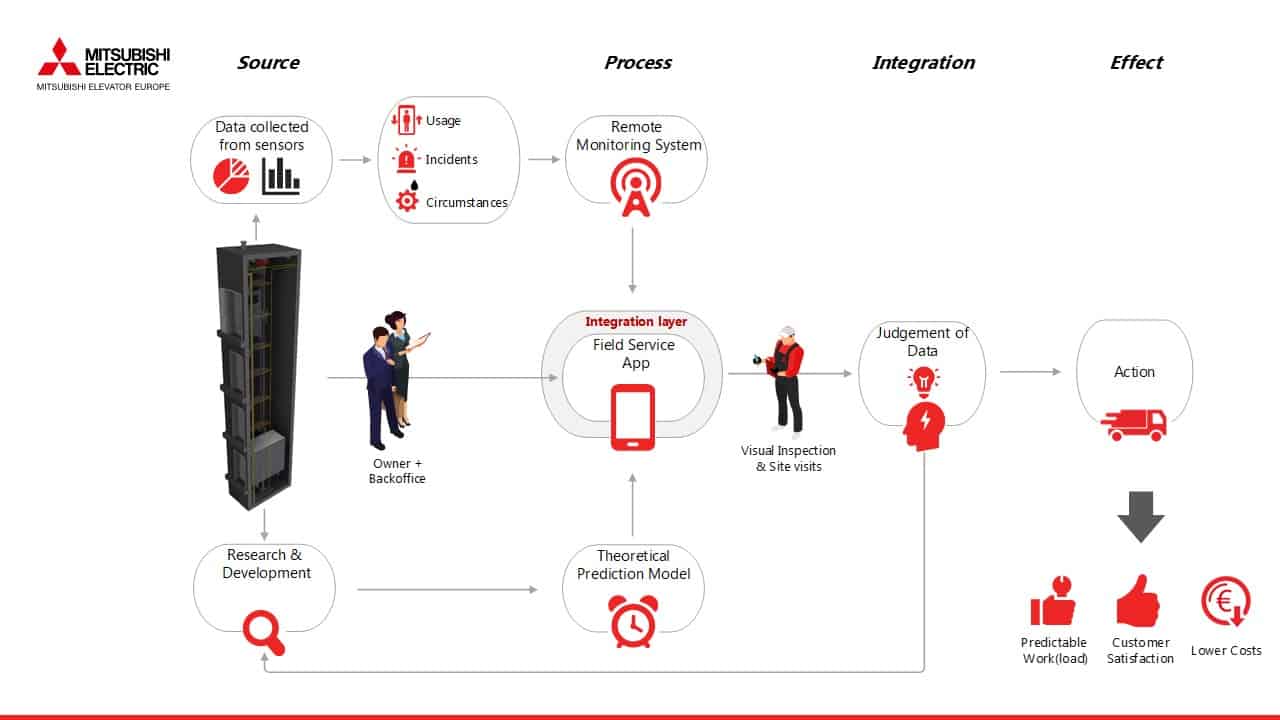

Mitsubishi is also working to create an integrated maintenance system. They began this process by developing and perfecting smaller, fit-for-purpose applications, then integrating them to deliver a holistic, valuable experience.

First, they’ve deployed a new field service application, mainly built for their maintenance engineers to “reduce their administration and support their job,” according to Visser. This app:

- Allows Mitsubishi’s back office to know where their engineers are at all times

- Ensures that the right engineer is being assigned to emergency jobs more quickly

- Creates time efficiencies and cost savings by avoiding unnecessary maintenance visits

Further, Mitsubishi already has IoT sensors collecting data from all their elevators, monitoring usage and incidents, such as heavy rain or floods. This data is sent back to a new remote monitoring system, which automatically schedules maintenance for any given elevator over an entire year. This helps not just in future resource planning, but also in reducing the organization’s carbon footprint by avoiding unnecessary service visits.

That sensor data also goes directly to Mitsubishi’s research and development team, who have developed a theoretical lifetime model for predictive maintenance which can be applied to the entire fleet of elevators.

These individual pieces have provided Mitsubishi with great data and have improved service for their customers, but their next step is to bring all three together into a single remote monitoring application.

“This information will be used as steering for our maintenance worker, together with his technical expertise,” Visser said. “He will make his own decision to change the component or keep it running or repair it, whatever he thinks is best.”

This model offers several benefits to Mitsubishi.:

- Improved customer experience as a result of better data leading to better maintenance.

- More proactive and predictable maintenance (i.e fewer emergency field service visits) thanks to the theoretical prediction model.

- A better employee experience due to better quality data, more efficient maintenance, and less frequent off-hours emergency calls.

- Cost and carbon savings for Mitsubishi, which allows them to then offer a lower service fee to customers.

Customer Satisfaction at the Forefront

When describing the choice to work with TimeSeries and Mendix, Visser described, “our vision is clear. We want to adopt new technology in a fast and sustainable way.”

Mitsubishi’s practical knowledge about their industry, coupled with TimeSeries’ knowledge of low-code and focus on speed, led to fast and effective results. Visser continued, “We want to grow together.”

Visser offered some advice to other organizations looking at building any kind of application with a partner.

The most important element for Mitsubishi, though, is their guiding star of unmatchable customer experience. Visser noted that AI, machine learning, predictive maintenance, and other emerging technologies are all important tools. “But, of course, what is most important, we have to keep the benefit for our customer in mind.”

That principle has allowed Mitsubishi to design new experiences for both internal and external users. As Visser said, “That’s not fancy talk. That’s not a fancy “we use machine learning or AI.” No, we improve the satisfaction of the customer.”