Mendix Improves Data Management for Apparel Manufacturing Enterprises with New PLM System

Founded in 1992, Xianbang Garments operates with 1,000 employees and manufacturing facilities in Hong Kong, Zhongshan, and Bangladesh. After 10 years of use, Xianbang’s legacy ERP struggled to keep pace with dynamic industry changes.

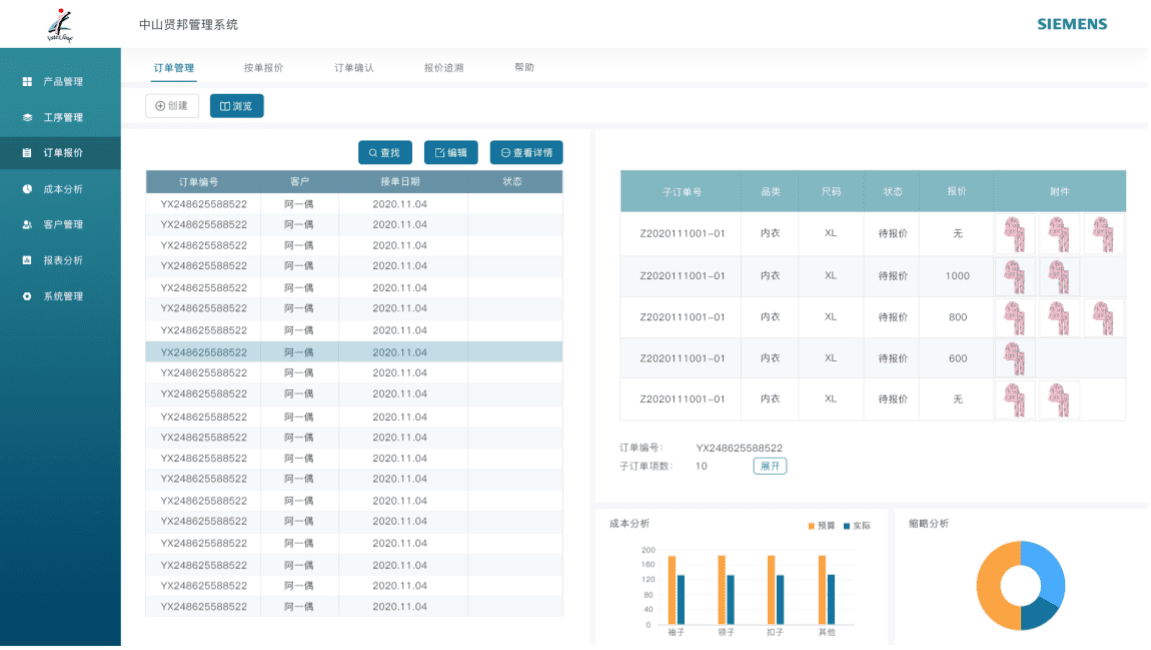

By utilizing the Mendix low-code platform, Xianbang developed a customized PLM solution tailored to the apparel and FMCG industries, seamlessly integrating with their existing ERP. This transition replaced 60% of ERP functions and established a robust foundation for smart factory initiatives.

The overhaul of legacy systems and creation of a new core system cultivated a capable, innovative workforce. This momentum propelled the company to define a strategic roadmap, integrating fragmented data and siloed systems into unified modules for data and process management, creating a virtuous cycle of innovation.

Challenges in the Apparel Industry

Despite its expertise in apparel manufacturing, Xianbang faced critical challenges:

- Inefficiencies in data management

- A lack of streamlined business processes

- Mounting competition leading to reduced profit margins

Their outdated ERP system, in use for over a decade, could no longer support the company’s ambitions for digital transformation. Xianbang urgently needed to modernize its systems to achieve precise cost management and accelerate quotation processes, crucial for boosting business growth and competitive edge.

In 2020, driven by the pandemic and remote work, Xianbang recognized the necessity of unified data control. Following a thorough evaluation of industry-leading solutions, Xianbang selected Mendix, impressed by its efficiency gains and scalability.

Backed by Siemens’ reputation for innovation, Xianbang partnered with Mendix and Nancal Technology to embark on its digital transformation journey.

Embracing Low-Code to Build New Systems

Before adopting Mendix, Xianbang’s order and quotation processes relied heavily on Excel spreadsheets, leading to inefficiencies and inaccuracies.

Mendix provided the perfect solution to these challenges. Xianbang leveraged the platform to build a lightweight PLM system tailored to the apparel and FMCG industries. Key achievements include:

- Seamless integration with the legacy ERP system, enabling efficient data retrieval and agile response to customer needs.

- Support for customer and supplier management, enhancing client selection and optimizing business processes.

- Customized design principles that reduced manual effort, improved business quality, and allowed employees to focus on strategic tasks.

- Centralized data sources combined with process-driven workflows, empowering informed decision-making through real-time analytics.

The first-phase PLM implementation was completed in six months. By standardizing quotation templates and automating workflows, Xianbang achieved:

- 30% improvement in quotation efficiency;

- 40% reduction in management costs;

- 50% decrease in communication overheads.

Building a Digital Future with Confidence

The PLM system successfully unified Xianbang’s scattered business data, enhancing workflow management and decision-making. It has become a critical tool in enabling Xianbang to adapt quickly to customer needs and maintain competitiveness.

In collaboration with Mendix and Nancal Technology, Xianbang completed the first phase of the project and is now laying the groundwork for the second phase.

Future plans include incorporating production, procurement, and inventory processes into a unified system, aiming for a 50% improvement in operational efficiency by 2022.

Charting a Path for Sustained Innovation

Having experienced the advantages of Mendix firsthand, Xianbang plans to maximize its value for future developments. General Manager Zheng Zhongxian expressed enthusiasm for the platform’s potential.

By fostering a culture of continuous improvement and leveraging the expertise of Siemens and Nancal, Xianbang is well-positioned to achieve its vision of becoming a fully digitized, innovative enterprise.