Vivix Transforms Glass Manufacturing for a Clearer Future

Glass might look invisible, but its impact is anything but ambiguous. It’s in the eyeglasses we wear, the mirrors adorning our spaces, the windows protecting our cars, and the glass incorporated in building construction.

However, the manufacturing of this versatile material is a complex process that requires a multitude of solutions throughout production.

Vivix Vidros Planos produces float, laminated, and mirror glass primarily for Brazil and Latin America. With over 350 employees producing 900 tons float glass per day, it’s the only glass manufacturing plant funded by 100% Brazilian capital.

Vivix’s unique position as the only glass company in Brazil with their own raw material plant ensures the consistent production of high-quality glass.

Sponsored by their Industrial Top Leadership and Innovation department, Vivix established an Industrial Transformation Department. In 2021, they formulated a three-year roadmap to accomplish digital transformation in manufacturing operations. The focus included digitalization, interconnection, interoperability, data infrastructure, management tools, and decision support.

The goals for their transformation included:

- Reducing operational costs

- Increasing the industrial teams’ productivity

- Improving resilience to global changes by becoming a data-driven organization

With the support of Siemens integrator, Mekatronik, Vivix began evaluating technological alternatives and strategies to address its complex business needs. The choice to embrace Mendix was reinforced by partner TrueChange, who offered platform definition, training, Hackathons, and technical support for a seamless implementation.

With the Mendix low-code platform, Vivix began digitizing various aspects of its glass production processes, including product traceability, production management, statistical process control, operational shifts checklists, and CAPEX management. By adopting low-code to increase efficiency and transparency, they are ensuring only the highest quality of glass hits the shelves.

Mending the Cracks in IT Delivery

The 5-layer automation pyramid is widely used in the manufacturing industry to understand how technology interacts at all levels of a plant’s complex operations. Vivix started its operations in 2013 and has since adhered to the Purdue model as a reference for enterprise architecture.

In partnership with Siemens, they achieved automation on layers 1 and 2, the field and control levels. Among the array of the Digital Siemens Software Division’s tools Vivix currently utilizes are Opcenter APS, Industrial Edge, PCS7, WinCC Unified, and WinCC Professional.

However, they still needed to tackle layers 3 and 4: operations management and manufacturing execution systems. “In the past, Vivix didn’t have a solid foundation for its data architecture and information for industrial processes,” explained Aristóteles Terceiro Neto, Industrial Transformation Manager at Vivix.

“Almost everything was done through Excel or on paper. When looking at layer four, the control layer, we used SAP. But almost all the information that was fed into it was data we consolidated manually.”

When searching for new development methods, Neto stated, “We weren’t necessarily looking for a low-code platform, but rather a solution or partner to fit in our ecosystem to create additional transformation.”

What they needed was a robust platform with enterprise-level capabilities to:

- Leverage the team’s engineering expertise throughout the software development lifecycle

- Eliminate paper processes that interfered with process efficiency

- Develop an end-to-end system that helped realize digital transformation

- Ensure compatibility with other systems of record such as SAP S/4 HANA

After evaluating over 18 solutions, they ultimately selected Mendix for its robust platform, market share, and scope. Other key differentiators included its:

- Intuitiveness, enterprise-grade capabilities, and ability to solve complex problems

- Ability to build edge and mobile applications deployed in environments completely bereft of any network connectivity, a common scenario found on many shop floors

- Reputation as a Siemens company with a roadmap and ecosystem of partners to support industrial demands

“Mendix is a good platform to start small and eventually scale up to what we need,” said Neto. “That’s why we started with the platform. Other alternatives have expensive licensing costs, and the partners don’t fit with our industry. Those hurdles make it very costly for companies like ours to start digital transformation.”

“The platform’s scalable microservice architecture, Mendix enables us to create several different service applications that communicate with one another. Also, the robust cloud offering was a huge benefit for us. The security, ease, and accessibility of Mendix Cloud meant we could focus less on deployment and more on our desired outcomes,” he added.

With Mendix being cloud-native, Vivix has the flexibility to adapt their deployment strategy as conditions change over time. They seamlessly transitioned from Azure to AWS due to the latter’s broader availability of partners and experience with implementing manufacturing data & analytics environments in the region.

Looking ahead, they are exploring leveraging Mendix for Private Cloud on AWS to further simplify setting up new environments and integrating with internal systems.

Vivix’s investment in Mendix also signaled a larger organizational shift towards innovation specific to glass manufacturing.

With a new path forward, Neto and his team immediately began developing solutions to improve their manufacturing delivery and transparency.

Transparency in Glass Production

While glass is a see-through material, transparency in its production is a challenge. Glass manufacturing is an intricate process that relies on time-consuming manual work. Automating it requires collaborating with those most familiar with its pain points.

After adopting Mendix, engineers from Vivix, TrueChange, and Mekatronik began creating applications for the maintenance, quality, EHS, logistics and production teams that encompass all stages of manufacturing.

Digitizing Engineering Checklists

Before Mendix, Vivix faced challenges in effectively monitoring maintenance procedures for their utilities teams. To guarantee that all production-related steps are meticulously executed, engineering process checklists are essential.

Alencar and her team first created a Checklist Application for workers in the field to address workflow inefficiencies. “During each shift, the team would lose four or five hours alone just from manual work,” Neto explained.

“They would take data and put it in a spreadsheet that would then generate graphics that visualize our data. They needed an app that directly tracks the information automatically from a checklist so we don’t lose time doing it manually,” added Alencar.

In just one month, Vivix built an application that:

- Streamlines task management

- Tracks checklist frequency

- Logs detailed observations

- Monitors delays

- Integrates with Vivix DataLake

- Curates action plans for improvement

“Without templates, we wouldn’t have been able to deliver so quickly. The front connectors use MQTT connectors, PDF widgets from the [Mendix] Marketplace, and other widgets for manual signatures. These resources improved our process overall,” Neto said.

“When the production values weren’t what we wanted, we couldn’t control the follow up actions. If we wanted to better manage the data, we would have to make yet another spreadsheet that would be managed by one person. The new system allows us to set a deadline, delegate responsibilities, track the status, and more. If any equipment is out of operation and needs maintenance, this is how we keep better track of that information.”

The Checklist Application also provides for greater efficiency and transparency across teams. “It can be easily adjusted for different purposes,” Alencar said.

“We are using it at the main entrance for the trucks and even chemical analysis. We have a dashboard that shows the answers and builds reports for us in Power BI. Now, we have requirements for a true action plan to make corrections, closely monitor glass profiles, and update our data,” she added.

Real-Time Temperature Regulation

Consistent glass quality relies on precise temperature regulation to reduce defects. To ensure precision, developers created a solution that visualizes the factory’s furnaces in real-time.

“Before, this process was tracked in an Excel spreadsheet,” Alencar explained. “We would manually input the data that would generate the regulation curves. In Mendix, we can see the comparisons of the automatic thermocouples because the data is directly extracted from our data unified namespace. It’s much easier for the team and much more accurate than before.”

Ensuring Product Quality

Glass quality reports play a crucial role in ensuring compliance with regulatory standards and monitoring overall manufacturing efficiency. By digitizing this step, Vivix has achieved a higher level of precision in process parameters and quality control.

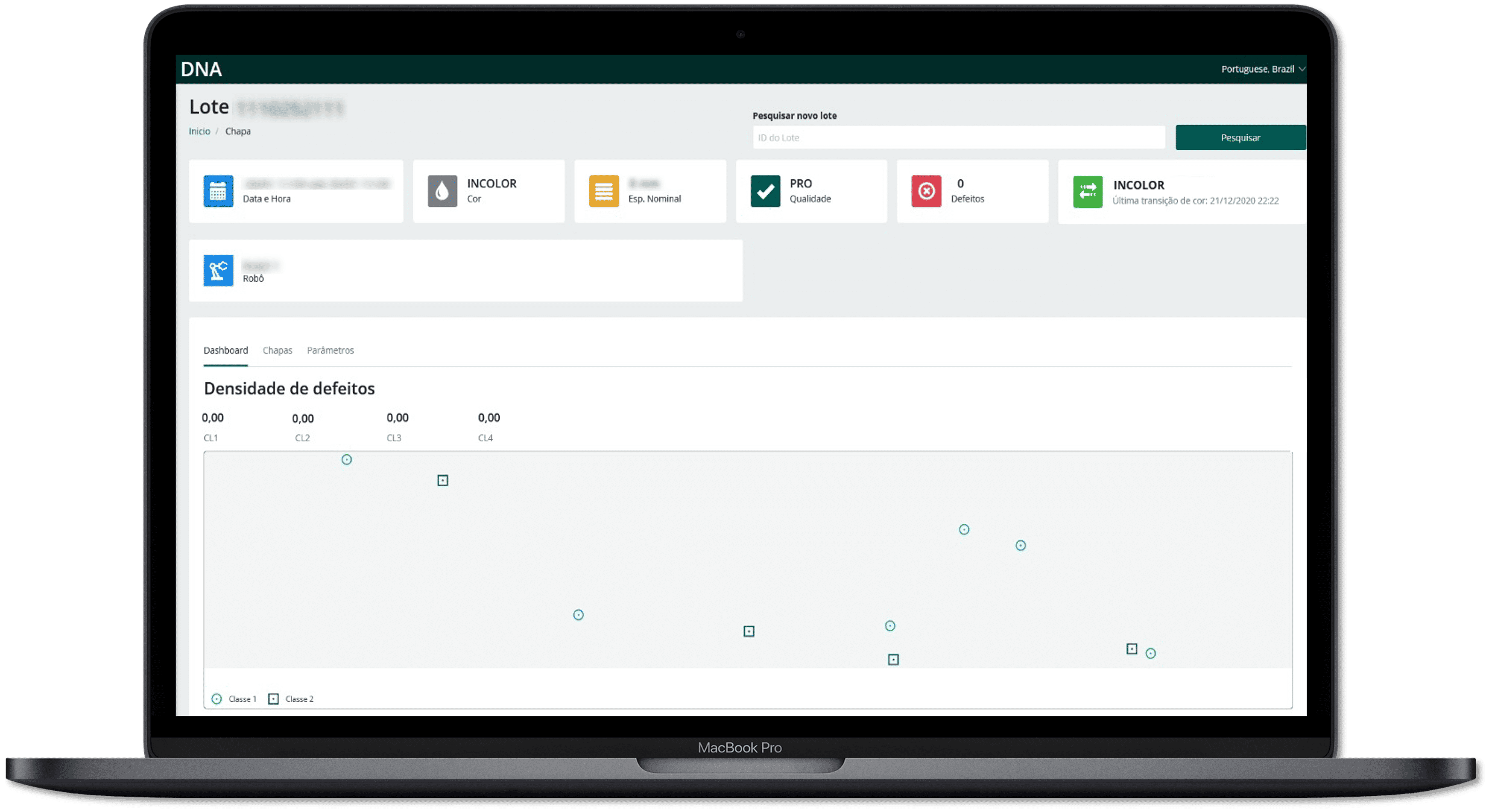

To analyze batches of glass more accurately for thickness, color, and quality, developers created a Digital Glass DNA application. This allows workers to easily monitor quality, promptly address any defects, and continuously adapt the product.

“For us, it’s good to see if we have a quality issue and check all parameters,” Alencar explained. She is especially proud of the connection between the Glass DNA app and Checklist Application.

“There is a link to our server that holds the historical data. On one hand, Glass DNA has a tag number that allows us to automatically access batch information. For non-automatic processes, we’re using the Checklist App as a data source. The information is going to be inside Checklist App and vice versa. They are linked.”

The integration between the Checklist Application and Glass DNA seamlessly merges with Vivix’s legacy systems of record, digitizing their data and eliminating the redundancy of paper-based processes.

Consequently, the Glass DNA application equips Vivix to actively monitor essential data points and identify any production losses. This ultimately enhances operational efficiency and transparency across every production stage.

Resolving Customer Complaints with Generative AI

To further elevate their customer experience Vivix is now infusing artificial intelligence and machine learning into its Mendix solutions. A chatbot, dubbed Virtual Engineer, gathers product, production and process data and offers tailored suggestions to the quality and production teams, enabling them to proactively address customer complaints.

The Virtual Engineer chatbot was built in collaboration with Deloitte Brazil and is embedded into the existing Glass DNA application. It integrates several data sources, including other Mendix apps, and Amazon Bedrock to invoke the Foundation Model, in this case Claude 3 by Anthropic.

Vivix expects Virtual Engineer to speed up the resolution of customer complaints from 5 days to less than one, and internal production issues from 4-5 hours to minutes.

Moreover, it will free up their experts to work on structural improvements instead of resolving individual issues.

Rapid Development Spurs Innovation

Vivix’s newfound rapid development capabilities allow them to address larger organizational goals without sacrificing the quality of their material or production efficiency.

“In addition to our new rapid development capabilities, we can innovate with Mendix because we don’t need to worry about things like security that are inherent to the platform,” Neto added.

Business engineers at Vivix are able to become productive Mendix developers in just a few weeks time and can start contributing to transformation projects with ease.

“It was good that I learned Mendix before leading the projects. I was able to set the expectations around what we could deliver and collaborate better with the development team,” she continued. “That ability combined with Agile meant we regularly communicated during daily or weekly product meetings.”

Adopting the Agile methodology gave Vivix an edge when developing their new solutions. “It gives us the power to work more efficiently overall,” Neto said. “Our users are involved in development using the Mendix platform because of Agile. We can look at historical projects and progress and prioritize their needs.”

A Clearer Future with Low-code

Low-code technology empowers Vivix to expand their automation architecture and enhance software delivery. By utilizing tools like Mendix and SAP, Neto and his team are advancing their digital transformation initiatives and addressing layers 3 and 4 of the automation pyramid.

In line with their forward-thinking IT strategy, Vivix was one of the first users of the SAP S/4HANA Cloud in Latin America, having migrated from SAP ECC in just one month. While SAP plays a critical role in their IT landscape, the user experience could sometimes be suboptimal for production line employees.

In these instances, the compatibility between Mendix and SAP becomes even more valuable, as Vivix can leverage the Mendix SAP OData Connector. Production line applications can be delivered with a modern, Mendix-based UI that is readily connected to SAP.

This approach enables them to keep the core clean while integrating new technologies into their distinctive processes. These efforts are all in alignment with the Vivix mission of “pioneering innovation every day with unwavering boldness, simplicity, and engagement.”

The propensity to innovate doesn’t just stop at manufacturing. The GCB Digital Solutions team is currently testing Mendix in areas such as supplier management and legal. Furthermore, the introduction of AWS services, AI, and Siemens Industrial Edge by way of Mendix continues to push the boundaries of what’s possible within Vivix.

“We plan to integrate even more AWS services and create more smart apps with AI to create barrier data workflows. We want our team to use generative AI to improve our reports and have a new perspective of our data. We are also deeply committed to expanding the use of Mendix Edge applications through Siemens Industrial Edge. Mendix 10 will help us achieve that as well,” he added.

Mendix has allowed Vivix to not only improve operational efficiency, but also broaden their range of possibilities. “With Mendix, high-quality solutions and rapid development are a guarantee. Since I know what the platform can do, I can think even bigger to make a larger impact,” stated Alencar.