Factorise Shopfloor Operational Excellence Platform

Elevate your shopfloor with Operator Centric, Data Driven apps based on Lean and TPM best practices.

Driving Data-Driven Operations

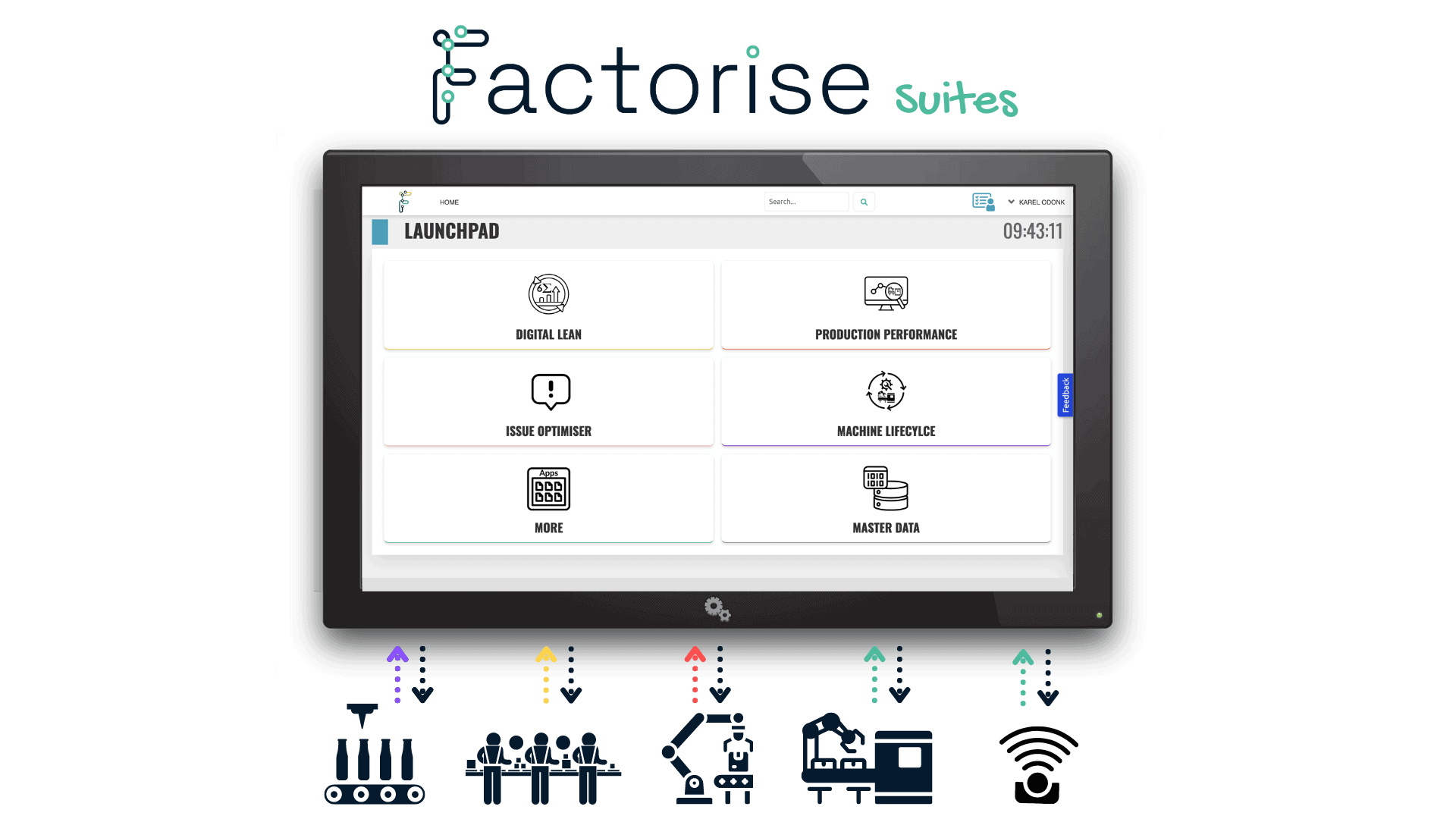

Empower your factory operations with our composable Shopfloor Operational Excellence platform. Our out-of-the-box suites are crafted to harness the power of Lean and TPM best practices, transforming your shopfloor data into actionable insights. Each suite is equipped with user-friendly, operator-focused apps designed for capturing, validating, and monitoring the vital data and processes of your factory shopfloor. With an emphasis on ease of use, these tools are tailored to facilitate real-time operational oversight.

Our integrated suites are the backbone of operational excellence, enabling operation managers, operators, and operational excellence teams to make data-driven decisions. By moving beyond opinions, our platform paves the way for substantial, evidence-based improvements. Enhance cross-departmental collaboration with easily accessible tiered boards that bolster process transparency. Our operator-focused approach to issue logging and action tracking, combined with robust lean problem-solving tools, fosters a sustainable culture of continuous improvement on the shop floor.

Discover the core components of our platform:

- Digital Lean: Unleash Operational Excellence through Data-Driven Digital Lean Operations.

- Issue Optimiser: Empower Your Shopfloor with Instant Insights and Streamlined Actions for Effective Issue Resolution.

- Production Performance: Unlock Real-Time Production Insights (OEE) Across Your Factory for Enhanced Short Interval Control.

- Machine Lifecycle: Achieve Superior Machine Longevity and Yield with Data-Driven TPM Maintenance.

- Elevate your operational potential with our Shopfloor Operational Excellence platform – where data informs decisions and continuous improvement is the standard.

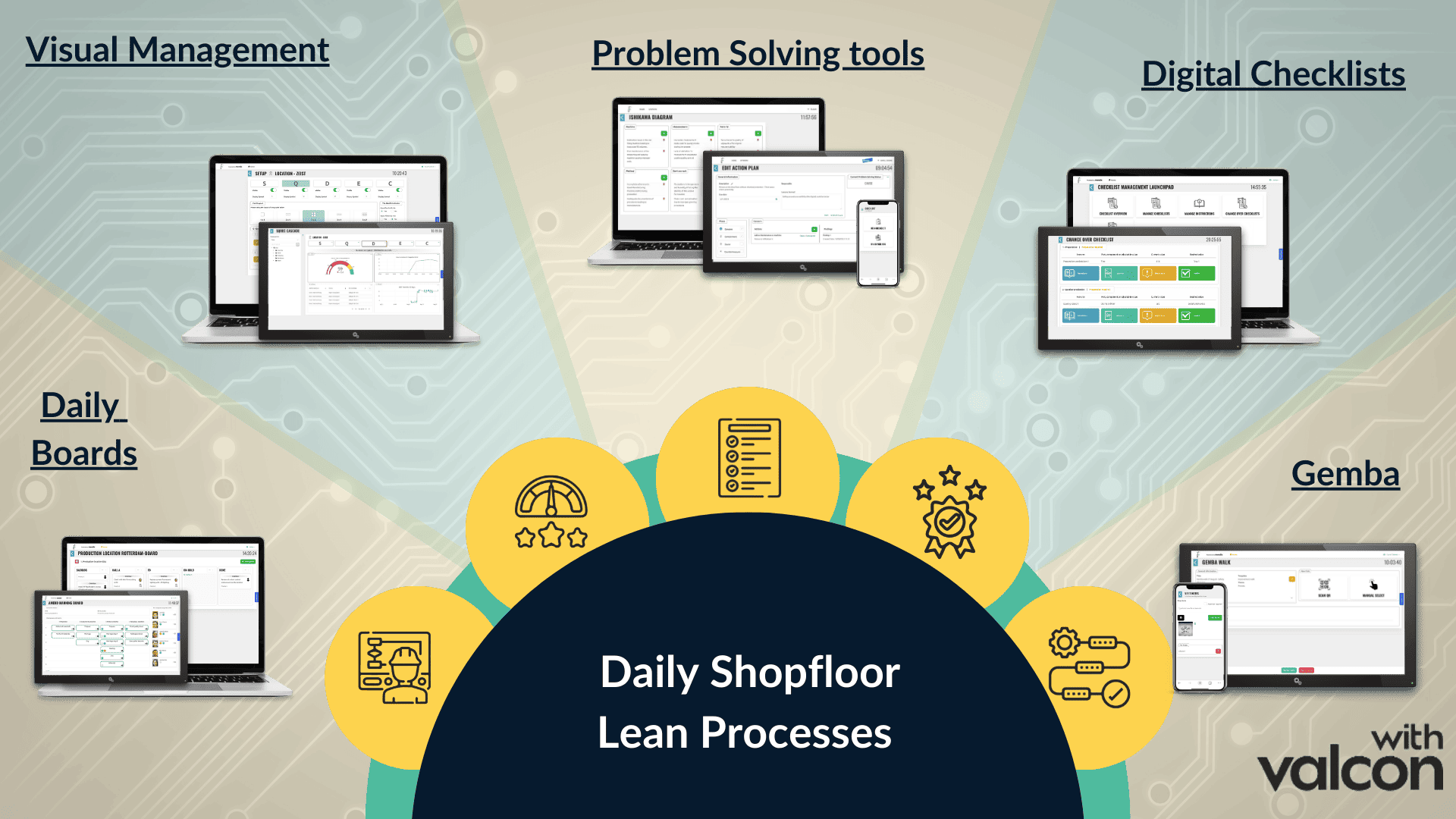

Digital Lean

Factorise’s Digital Lean suite helps manufacturers successfully implement lean principles on the shop floor through data-driven insights and process automation. By digitizing daily lean management tools like Gemba walks, daily huddles, and manning boards, Factorise provides real-time visibility into production performance so issues can be identified and addressed immediately. This helps eliminate waste, increase efficiency, and continuously improve work processes. Digital Lean allows managers to spend more time solving problems instead of just finding them. Employees stay engaged on improvement efforts through a centralized platform to track progress.

One platform integrated with your OT

Factorise provides manufacturers with a fully integrated digital operations platform that connects important shop floor data from sensors and machinery to powerful production management applications. Unlike disparate point solutions, the Factorise platform ensures a unified digital thread throughout the enterprise by integrating operational technology (OT) data with key lean and performance management processes. All of Factorise’s configurable applications like Digital Lean, Issue Optimiser, machine Lifecycle and Production Performance can be seamlessly combined to support an end-to-end digital workflow. Standardized data definitions and connectivity options simplify IT integration while providing automated data collection at scale. With a single platform to manage Standard Operating Procedures, checklists, OEE calculations and more, Factorise customers benefit from consistent real-time visibility, unified governance of KPIs and integrated decision making. The platform’s composability allows customized solution stacks that uniquely address specific manufacturing challenges and priorities

Additional Solution Capabilities

Solution Integration

Ready to get started

with this solution?

Fill this out and we’ll reach out shortly.