Siemens Global Business Services Democratizes App Development

Siemens is a company of makers.

Its founder, Werner von Siemens, created the world’s first electric railway, dynamo, and telegraph, which functioned as a point-to-point text messaging system avant la lettre, more than 170 years ago.

Since then, the German multinational conglomerate has shaped industrial revolutions in Germany, and across the world, leading movements of electrification, automation, and industrialization. The company focuses on infrastructure, industrial energy, mobility, and healthcare.

In 2019, it reported a revenue of 87 billion euros and employed 380,000 people worldwide. About 40,000 of those work in digital jobs at Siemens.

Over time, however, some of its core software systems had become outdated. More than 60 SAP systems were in use across the organization, making it difficult for employees to access, record, and process business information. Driving innovation in an environment such as this, where data is murky, becomes increasingly hard.

Siemens Global Business Services (GBS)

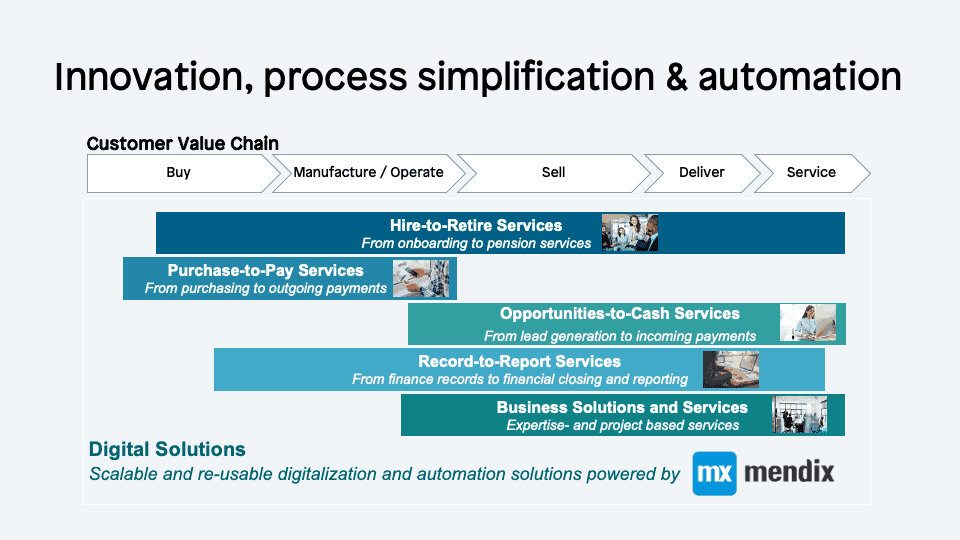

Siemens Global Business Services (GBS) designs, innovates, and efficiently operates business services for Siemens units and external customers. Its portfolio comprises transactional, as well as expertise-driven services, with a strong focus on digitalization in areas like:

- Business administration

- Human resources

- Supply chain management

- Sales & marketing

- Engineering

GBS serves its clients globally out of 11 major delivery locations and more than 40 branch offices with a workforce of about 9,500. GBS headquarters are based in Munich, Germany.

In the past, it would bundle such requests, creating synergies, and offshore it to lower-cost countries. This is sometimes called labor arbitrage. For example, workers in Bangalore, India, handled a large portion of accounting requests (purchase-to-pay orders, order-to-cash, or record-to-report services.)

Beyond providing services, employees of Siemens GBS, and Siemens, at large, are enabled by software built and maintained by the team.

Investments in intelligent automation technologies—robotic process automation, chat bots, artificial intelligence, and business process management platform—work towards that goal. One particular investment, Mendix, has delivered on a very tangible promise.

Building User-centric Applications with Mendix

The need for change was driven by three major needs:

- Relieving employees working at GBS (Siemens’ IT arm servicing business departments around the world) from switching to different applications depending on the task at hand

- Eliminating manual or redundant tasks

- Improving transparency on the overall status of their work process

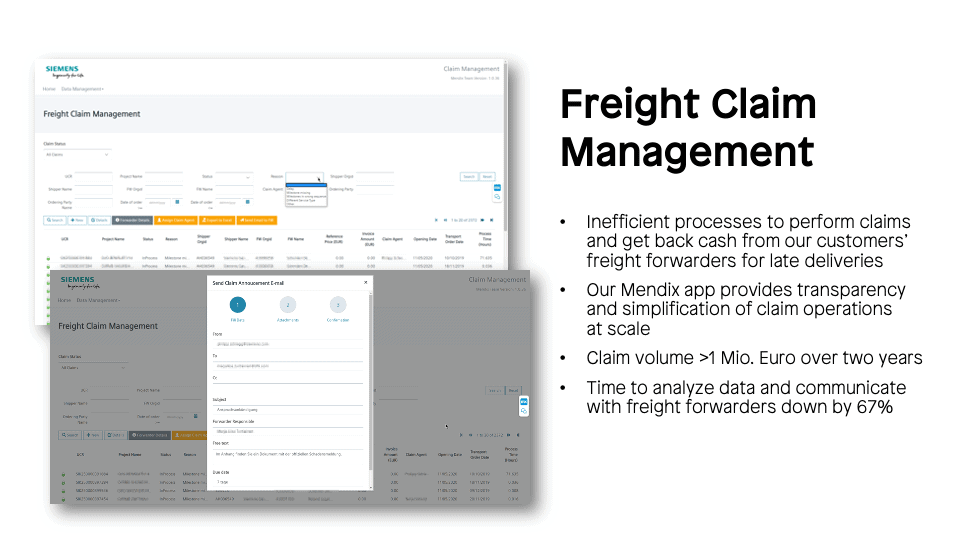

First Application: Freight Claim Management

In February of 2020, a Mendix team of business consultants supported GBS in developing its first application: a new tool that manages and tracks every step along the journey of a piece of equipment shipped from one of Siemens’ global manufacturing sites to a customer location.

GBS gathered a small team consisting of two developers, a scrum master, and a product owner from the logistics department to build the application.

When Siemens sells a product to customer, anywhere in the world, an invoice is delivered containing the details of the customer agreement at the time of the sale, including a price and delivery date.

If, for whatever reason, the product is delivered late, or doesn’t comply with the terms, the customer can file a claim. GBS investigates what went wrong (for example, how many hours was the shipment late by; how should Siemens adjust the price and address the claim potential). Next, claim managers, with the help of the application, calculate the difference and the amount owed.

In the old system, these claims were stored in an aging SAP framework that didn’t serve the company’s needs. It was difficult to access data across the various systems and to exchange data between Siemens’ systems and its partners.

Thanks to the Mendix development platform, GBS was able to deliver an application that centralized all claims within six weeks.

Claim managers at Siemens’ business departments can now see, filter, and share claim information with freight forwarders. (Freight forwarders are companies that deliver goods and organize their logistics from a manufacturer’s warehouse to its destination. Major players in the industry include DHL Global Forwarding, Sinotrans Ltd., and DB Schenker.)

The impact of this first application was tremendous: The time for claim managers to analyze data and communicate with freight forwarders was reduced by 67%.

Ultimately, the solution was built 4x faster than originally anticipated. This had a multi-million-dollar impact (for comparison: the total value of outstanding freight claims was more than one million dollars over a period of two years), delivering a staggering ROI of 2,400% thanks to:

- Direct revenue from offering the service to freight forwarders

- Operational efficiency

- One-time savings resulting from the extra development time

They reached this success through teamwork: Adopting an agile mindset and approach meant that employees were encouraged to take ownership of their project and aim for record speed and quality. Accelerating their success was the use of a starter package, inclusive of consulting and expert services, helping the GBS team create customized templates and build a strong foundation for success.

A significant output of this work is the assurance that all developed applications will integrate with Siemens corporate entitlement services and utilize single sign-on.

Their approach paid off: The project was selected among the best 15 out of more than 500 within Siemens globally. As a result, new applications, delivered at even faster speed, are in the works.

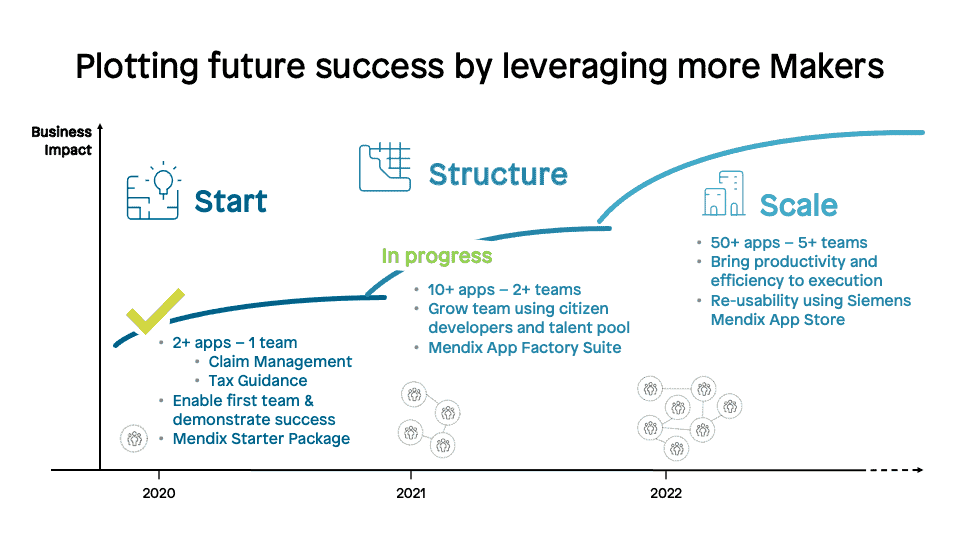

Scaling Up

GBS is in the process of building a global community of Mendix Makers to grow and scale the service. They’ve trained developers across GBS centers globally and they plan on adding many more. Citizen developers, who will take over the operation and maintenance duties of the apps, are onboarded on various business departments across the organization.

At the same time, GBS is investing in skill-building and attracting new talent such as solution architects and UI/UX experts. In a third phase, GBS is planning on scaling its operations.

The launch of a dedicated GBS App Factory, delivering applications to be made available to users across the world, is now underway, and will serve as a focal point of digitization in the coming years. Three teams are currently delivering applications, and will grow to five soon, teams will either be dedicated to one line of business and implement their own portfolio of applications; others will operate cross-functionally.

At the end of 2020, the size of the portfolio delivered by these teams swelled to nine applications in production, two underway, and 21 in pipeline, spanning use cases from:

- Budgeting & forecasting

- Coordinating shipping containers

- Managing fleets of company cars

The GBS team’s journey to automate the world’s business processes thrives on great design, agile development, and an ever-growing community of makers inspired by adding value, and the scope of their work is primed to expand to new heights in the years to come. Stay tuned.